Improvement of conductivity of CNT/resin composites

One of the major applications of CNTs is to compound CNTs into resin to achieve electric conduction, such as antistatic materials. In most cases, however, the conduction performances are not good than expected. The operators always doubt about dispersiveness of CNTs and the unexpected performances are due to bad dispersing quality of CNTs.

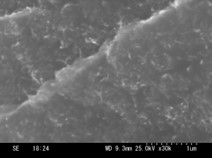

In the progress of our R&D, we found that, not only the dispersing quality, but also another key factor, as we call "surface tension effect (ST effect)", is an important factor for improvement of conduction performance. When melted resin mixed with CNTs are cold and cured to form a molded object, the resin on the surfaces of the object will push CNTs inside of the surfaces due to the surface tension force of resin, so that a resin-rich surface as called "skin layer" is easily formed, which drastically reduce the conduction performance.

This ST effect will be play more important role than dispersing quality when initial CNT additive ratio is higher. The ST effect is dominantly appears when mold injection method forming molded objects.

We have developed an after-treatment process to re-melt the object surfaces, and also a surface cooling technique by which the ST effect is reduced. By using these techniques, the conduction performance can be improved in a factor of 50-100 times.

We do technique consul services and give advices.