Desk-top CVD System for CNT & Graphene Synthesis

MPCNT-Premium

Easy synthesis of CNTs & graphene

Main unit of MPCNT-Premium

*Appearance and specifications are subject to change without notice.

Video: Growing of long-length powder CNT (X32 fast forwarded)

| Outline: | The premium model of the desktop CVD system, equipped with a multi-gas-introduction unit and a catalyst-precursor-heating filament, is designed for growing long-length (>200μm) carbon nanotubes in both powder and vertically-aligned films, and also graphene films on Ni foils. |

|---|---|

| Features: |

|

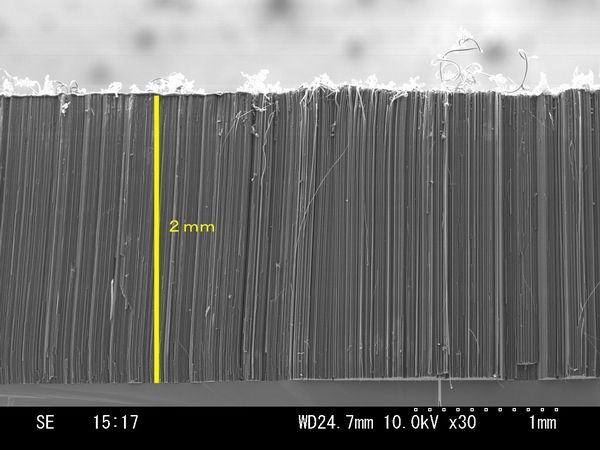

Vertically-aligned long-length CNT

As-grown long-length powder CNT from single batch

This min-size high-performance CNT synthesis system is an enhanced version of MPCNT-Basic with advanced features such as a catalyst precursor heating mechanism and multi-gas introduction mechanism. It is capable of synthesizing vertically aligned CNT on substrates and powder CNT in large quantities.

The catalytic precursor heating mechanism is a standard feature of this system. Subliming a catalytic precursor using heated filament enables catalyst to be deposited on substrates or powdery catalyst-support materials, so that a separate catalyst-formation apparatus and process are not required. This makes the system a complete CNT synthesis system which realizes catalyst formation and CNT formation at the same time.

Also, the heated filament generates activated radicals in large quantities and accelerates CNT formation. This makes it possible to easily grow long-length CNTs (length 50μm-2mm).

The multi-gas introduction mechanism is also a standard feature of this system. This system can introduce hydrocarbon gas (methane, ethylene, or acetylene) and hydrogen gas, as well as ethanol liquid. The types of synthesized CNT vary depending on the types of source gas. For example, the combination of acetylene gas, catalytic precursor, and powdery catalyst-support materials produces long-length CNT in powder form. The combination of ethylene gas, Fe/Co catalytic membrane, and a small amount of water produces SWCNT. The combination of ethanol and Fe powder produces carbon nanocoils.

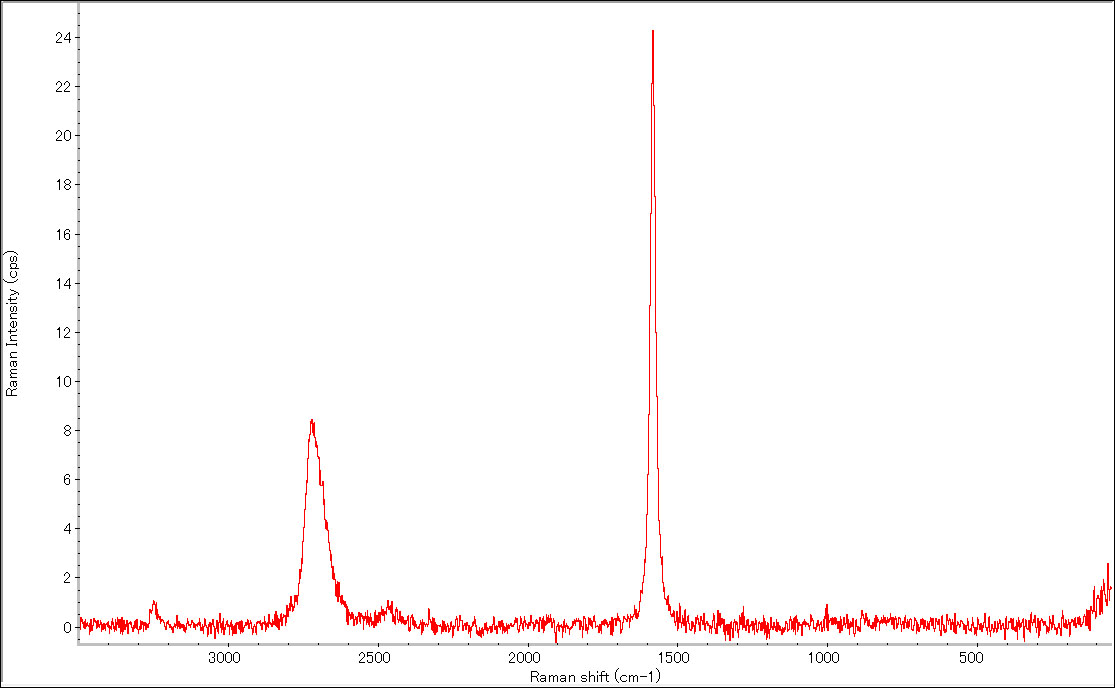

Raman spectrum of graphene (core shell structure) deposited on Ni particle surface

Figure of system components

Specifications

| Configuration | Main Unit |

Grass Chamber Gas Introducing Port Vacuum Pump Port Leak Port Vacuum Gauge Current Terminal Dimension:W400㎜×H360㎜×D265㎜ |

| Multi Port | Gas Introducing Port_3 | |

| Gas Introducing Port_3 |

25㎜×40㎜ Operating Temp.:400~800℃ |

|

| Firament Heater | Operating Temp.:Under 1000℃ | |

| Power Supply for Heater |

for Substrates Heater, for Firament Heater Output Power:400W AC90-250V single-phase 50-60Hz Dimension:W110㎜×H130㎜×D405㎜ |

|

| Vacuum Pump |

Oil-sealed Rotary Vacuum Pump Dimension:W156㎜×H200㎜×D300㎜ |

|

| Thermometer for Heater | Fixed Radiation Thermometer | |

| Holder for Ethanol | ||

| Option | Gas Flowmeter |

Introduced Gas:Three Types Purge Gas [N2 or Ar] Reducing Gas [H2] Hydrocarbon Gas [CH4 or C2H4 or C2H2] |